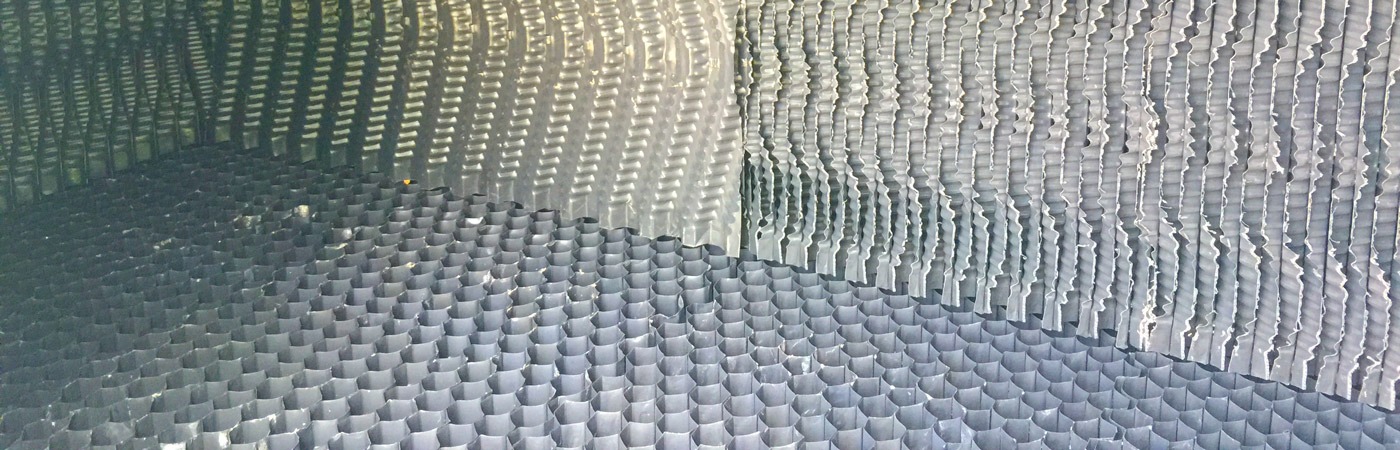

CIP Cooling Tower Pack Cleaning & Disinfection System

Paragraph 138 of the ACoP deals with the cleaning and disinfection of cooling tower pack where it is not practical to remove the tower packing. Although removal of the tower pack for cleaning is regarded as best practice by the HSE, alternative methods of cleaning the tower may be considered where there are practical difficulties in doing so. The efficacy of these alternative procedures must be verified.

How Does It Work?

The Accepta pack cleaning system works to create a stable wet foam that will flow slowly through the tower packing cleaning, descaling and disinfecting as it progresses. It is mildly acidic so as to remove inorganic scales. When the stabilised chlorine dioxide component to this system is added to the foam concentrate, chlorine dioxide is released into the foam. The release of the chlorine dioxide significantly aids disinfection.

Cooling Tower Pack Cleaning Components

- Accepta Activ-Ox Foam Cleaner is a high performance foaming cleaner developed for the in-situ cleaning of cooling tower pack components. It is especially useful where it is not practical to remove the tower packing… more >>

Tower Pack Cleaning Procedure

This cleaning procedure is based on the use of the Accepta CIP Tower Pack Cleaning products listed above and is intended for the routine cleaning of cooling towers. It is not to be used for the descaling of badly fouled towers.

Where a tower is heavily fouled an assessment of the nature and degree of fouling must be made, and then an appropriate remedial procedure must be carried out.

The HSE’s Approved Code of Practice, L8, requires the following steps:-

- Pre-clean and disinfection

- Pack removal and manual clean of the system

- Post clean and disinfection

The basic steps in this alternative procedure are as follows:

- Pre-clean and disinfection.

- Foam the pack.

- Rinse the pack thoroughly with defoamer and neutraliser.

- Inspect the packing to verify the process has been effective.

- Manually clean the tower to remove all debris etc.

- Post clean disinfection.

Foaming the Pack

Do not use these products to clean evaporative condensers.

The chlorine dioxide is present to assist in the removal of biofilms and to provide additional protection to operatives. It is not present to eliminate the necessity for either of the usual disinfection stages.

The foam is generated and applied through a suitable pressure jet washer fitted with a venture device and foam lance. The venturi must be fitted between the pump and the lance, not before the pump, as this cause damage to the pump. The venturi must be capable of mixing 10% detergent into the water. At 10% dilution, the detergent will contain 50ppm chlorine dioxide, this can be confirmed using Accepta chlorine dioxide test strips (0 – 100 ppm).

The foam lance should be capable of generating wet clingy foam. Dry dense foam is not suitable as it does not penetrate the pack and takes a long time to travel through the pack.

Appropriate health and safety measures should be taken working at heights on slippery surfaces and when using hazardous chemicals.

Foam the top of the tower generously. As the product penetrates reapply the product. Continue to apply the foam as required to maintain a steady stream through the pack. As the foam exits the pack test the acidity and chlorine dioxide levels. The results will indicate the extent of scaling and fouling with organic matter.

Continue to foam and test until the foam exiting the pack has an acidity and chlorine dioxide level close to that of the original detergent. Leave the remaining foam in the pack for half an hour.

Treat the spent detergent in the tower sump with defoamer and neutraliser. Rinse the pack with clean low pressure water.

The interior of the pack can be inspected using an endoscope.

If the condition of the pack is satisfactory, continue to clean the remaining parts of the tower and follow the post-clean disinfection procedure. If necessary and considered beneficial, repeat the foaming procedure and then continue the cleaning and disinfection process as normal.

If the product procedure has not achieved a satisfactory level of cleanliness within the pack the strategy for cleaning the tower must be reviewed.