Membrane Separation Technologies – Techniques for Minimising Wastes & Effluents

- heavy metals;

- anions (metals and non-metals);

- organics;

- water in organics.

It also considers the separation of gases and liquids.

Environmental best practice

This guide is intended to help companies decide whether separation technology can be used to minimise their waste streams and, if so, to indicate the most appropriate technologies available.

For each of the technologies examined, this guide first discusses the general principles of the technology, its typical applications, main advantages and disadvantages and approximate costs.

It then considers issues such as the technology’s efficiency and limitations, scale of operation, the main outputs and any ancillary plant required.

The choice of technology in any situation will depend on the specific nature of the streams involved. However, this guide offers guidelines as to the likely suitability of each technology for certain tasks, basing its conclusions on that technology’s general characteristics.

In some cases, a technology is applicable to the removal of a whole range of substances. Reverse osmosis and nanofiltration, two membrane separation technologies, can, for instance, be used to remove dissolved heavy metals, anions, organics and water in organics. The same is true for evaporation.

In other instances, a technology has a much narrower application. Adsorption and air stripping are only used in the separation of dissolved organics, for example. Some technologies fall between these two extremes.

The main application of the various electrical technologies, for instance, is in the removal of dissolved heavy metals and anions, and the same is true for ion exchange and precipitation techniques.

In the separation of gases from liquids, demisters and electrostatic precipitation techniques are used to remove mists in gas streams, while defoaming technologies and separation vessels are used where bubbles of gas occur in a liquid and also for treating two-phase mixtures.

Guide Contents

Contents of the guide include:

- Selecting the appropriate technology

- Separation of dissolved substances from liquids using:

- Adsorption

- Ion exchange

- Precipitation

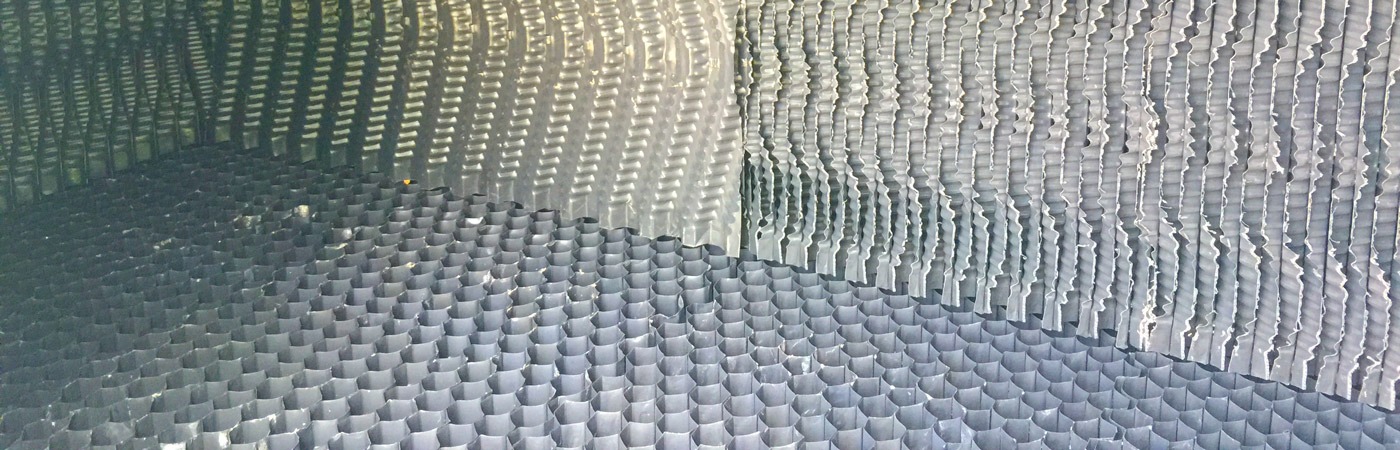

- Membrane technologies

- Electrical technologies

- Evaporation

- Distillation

- Dissolved air flotation

- Air/steam stripping

Separation of gases

Separation of gases from liquids using:

- Separation vessels

- Defoaming technologies

- Demisting technologies

- Electrostatic precipitation… request a copy of the full document >>

Extracted from a guide originally published by the Environmental Technology Best Practice Programme – © Crown copyright